As the chill of winter sets in, a warm, lightweight goose down duvet becomes a top pick for many Americans looking to stay cozy. But walk into any bedding store or scroll online, and you’ll be bombarded with claims like "Hungarian Royal Goose Down" or "Rare Siberian Goose Down"—and price tags that jump wildly as a result. Too many shoppers fall for the "origin myth," forgetting the core truth: a goose down duvet’s quality has nothing to do with "pedigree."

Globally, goose down production is widespread. In Asia, China, Japan, South Korea, and Vietnam all have steady outputs—breeds like China’s Emeishan White Goose and Xinjiang Ili Gray Goose yield down that meets international quality benchmarks. Europe leads with Hungary, Poland, Germany, and France; Canada is North America’s go-to source.

Hungarian White Geese and German White Geese are common in their regions, while Siberian breeds have unique cluster shapes due to cold climates—but that doesn’t make them inherently better. The American Down & Feather Council (ADFC) and ASTM International, the gold standards for U.S. bedding, make it clear: quantitative metrics, not origin labels, define quality. Hyping "origin pedigree" without talking specs is just a shady marketing trick.

The Secret to Goose Down Warmth: Nature’s "Air-Trapping Magic"

Why is goose down the "warmth champion"? The answer lies in its unique microscopic structure. Goose down isn’t a single fiber—it’s a 3D, spherical cluster made of a central core and radiating filaments, like a puffed dandelion. Each filament is stacked with thousands of hollow scales, and the nodes on these scales trap tons of still air. Gaps between clusters lock in even more air, creating an unbeatable barrier.

Heat transfers through conduction, convection, and radiation—and conduction is the main culprit for cold drafts in winter. Still air has extremely low thermal conductivity, making it a natural insulator. Compared to cotton, wool, or silk, goose down’s cluster structure traps more air, forming a thicker insulating layer. That’s why it feels "light as a cloud but warm as sunlight." Testing shows 95% down cluster content delivers over 3x the thermal resistance (TOG rating) of cotton of the same weight.

7 Hard Metrics for Top-Tier Goose Down: End Blind Buying

To judge a down duvet’s quality, focus on these 7 quantifiable metrics—they’re the down’s "quality ID card."

1. Down Cluster Content: The Foundation of Warmth

Down cluster content refers to the percentage of 3D down clusters in the filling—it’s the #1 factor for warmth. Measured by certified labs (per IDFL protocols), higher cluster content means plumper clusters and better heat retention. The ADFC requires at least 70% cluster content to label a product "down," while premium goose down duvets hit ≥95%. 2025 industry data shows upgrading from 80% to 95% cluster content boosts TOG (Thermal Overall Grade) from 3.95 to 6.80—that’s a 72% warmth increase! Critical note: "Down content" ≠ "cluster content." The former may include tiny fibers and fragments; only "cluster content" counts for real warmth.

2. Fill Power: The "Magnifier" for Warmth Efficiency

Fill power measures the down’s natural loft—how many cubic inches 1 ounce of down occupies when fluffed. It’s the non-negotiable standard for U.S. shoppers. Budget options hover around 600 FP, while premium down duvets need ≥800 FP (the sweet spot for warmth and lightness). Top-grade down from regions like Xinjiang and Hungary hits 800+ FP, meaning a small handful can fill a liter-sized container. Higher fill power = more air trapped per ounce, so your down duvet insert stays warmer without feeling bulky—perfect for year-round use.

3. Turbidity/Oxygen Demand: The "X-Ray" for Cleanliness

These metrics reveal how well the down was washed and sanitized—non-negotiable for allergy sufferers. Turbidity tests water clarity after washing; premium down scores ≥800mm, with top grades reaching 1500mm (far above FTC minimums). Oxygen demand measures contaminants; lower = cleaner. Poorly washed down harbors bacteria, odors, and allergens—violating California’s strict down product regulations. ADFC standards mandate ≤1.2mg/100g oxygen demand for premium grades, ensuring safe, fresh filling.

4. Residual Fat Content: The Balance Between Comfort and Durability

Residual fat content is a tight balancing act. Too much fat causes a "gamey smell" and bacteria growth; too little makes filaments brittle and short-lived. Industry standards peg ideal levels at 1.0%-1.2%—enough to keep down soft and resilient, no odors included.

5. Down Proofing: The "Guardrail" for Long-Term Use

Down proofing—how well the shell keeps down from escaping—depends on both down quality and fabric. Premium down duvets use 600+ thread-count cotton or microfiber with tight weaves, plus secure box stitching. FTC regulations and FTMS 191 Method 5530 (the U.S. military’s down-testing standard) allow no more than 10 escaped filaments per square meter. Larger, intact clusters are harder to push through fabric gaps—another reason full clusters beat fragments.

6. Fill Weight: The "Volume Knob" for Warmth

Fill weight is the actual grams of down in the duvet. Warmth increases with fill weight—but not infinitely. For a 90% cluster down duvet, going from 250g to 1200g fill boosts TOG from 4.46 to 12.52. But over 1200g, too much filling compresses clusters, reducing loft and warmth. Choose based on your climate: 800-1000g works for mild Southern winters; 1200g is perfect for frigid Northern nights. No need to overbuy!

7. Goose vs. Duck Down: Avoid the Bait-and-Switch

Goose down outperforms duck down for a simple reason: geese mature 3-5x slower than ducks, growing larger, fuller clusters (20% bigger diameter) with better insulation. Microscopic tests tell them apart—goose down has thicker filaments and distinct nodes; duck down is thin and fragment-prone. Shady brands mix "crushed duck down + fibers" into goose down duvets—always ask for breed verification.

7-Step Buying Guide: How to Pick the Best Duvet Down In-Store

Know the specs? Great—now use these hands-on tricks to test any down comforter on the shelf.

-

Check the Label:Legit down duvets follow FTC labeling rules, listing manufacturer info, filling type ("goose down," not just "down"), cluster content, fill weight, fill power, and fabric. Look for certifications: Responsible Down Standard (RDS) for animal welfare, OEKO-TEX® for chemical safety, or ADFC approval. If it only says "90% down content" without cluster numbers—walk away; it’s likely padded with cheap fibers.

-

Test Loft Recovery:Flatten the down comforter, press firmly, then release. A quality one bounces back fully in 3-5 seconds. Slow or no recovery means low cluster content or damaged clusters.

-

Feel the Texture:Squeeze gently—premium down is soft with no hard quills. Soft but limp? It’s treated feather fragments, not down. Tiny hard bits mean crushed feathers—steer clear.

-

Check for Dust:Pat the comforter hard. No dust = clean, high-quality filling. Dust means poor washing or crushed feathers—bad for allergies.

-

Test Down Proofing:Rub the surface hard for 1 minute. No escaping filaments = good down proofing. Loose down means it’ll thin out fast.

-

Smell It:Sniff closely. Top-tier down goes through 12+ washes (double the industry average) and smells like nothing. Gamey or chemical odors mean high fat content or harsh detergents.

-

Weigh It:A good rule: same size, lighter = better. A queen-size down duvet with 35oz (1000g) fill should weigh under 4.2lbs (1.9kg). Heavier means mixed feathers or low fill power—you’re paying for weight, not warmth.

Top Pick: apsmile Goose Down Duvet—Hotel Grand White Goose Down Comfort at Home

With all this know-how, you could spend hours comparing options—or skip the hassle with apsmile, the brand that builds "quality textbooks" into every down duvet insert. apsmile specializes in premium bedding, turning industry standards into tangible comfort.

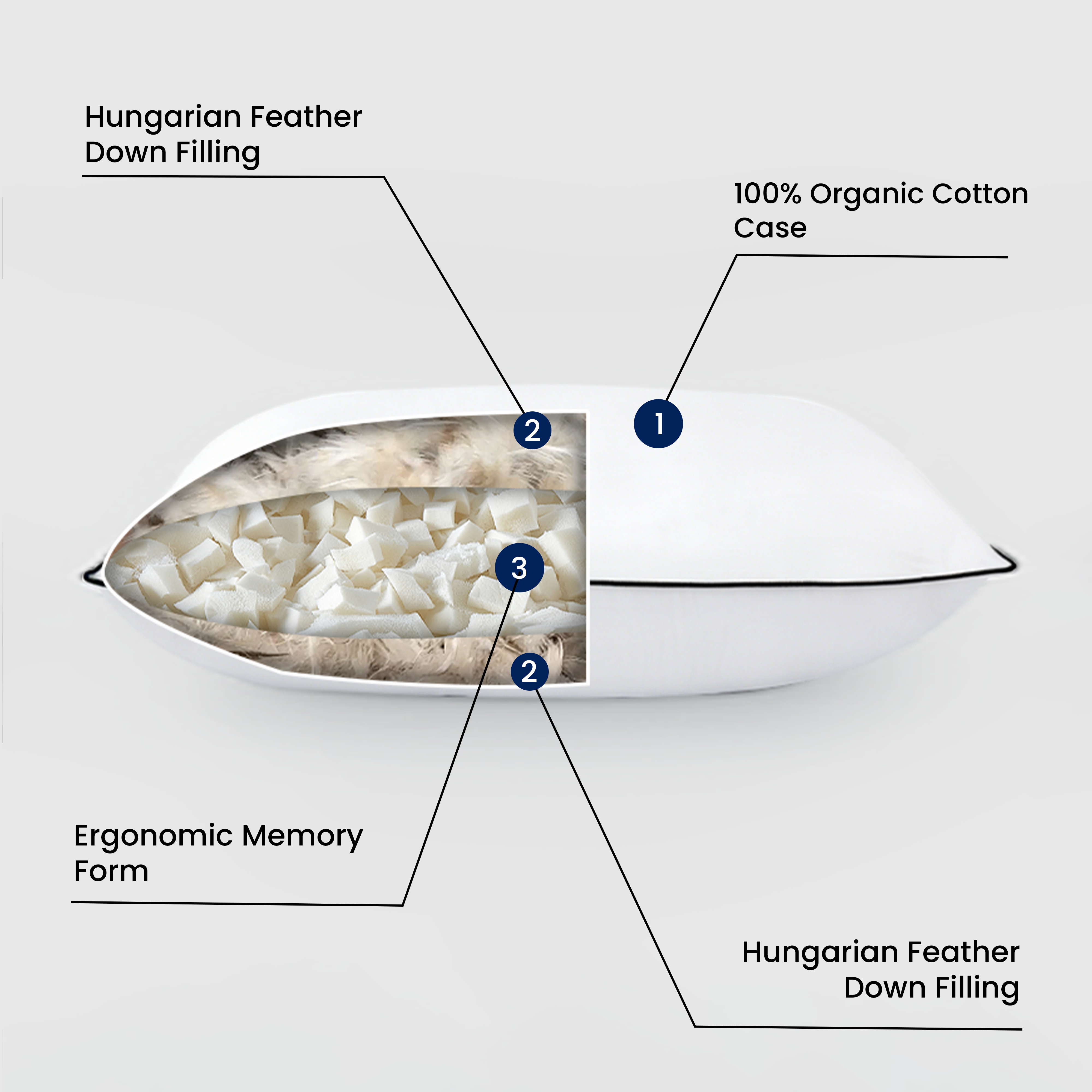

Start with the core: apsmile sources top white goose down from both Xinjiang, China, and Hungary—regions known for large, resilient clusters. It hits 95% cluster content (way above ADFC’s 70% minimum) and 800 FP fill power—meeting the strict standards of luxury hotels. After 15 ultra-pure water washes (double the ADFC requirement) and cold-air sanitization, it reaches 1500mm turbidity and 1.0% residual fat content. No odors, no allergens—perfect for sensitive sleepers, and fully RDS-certified.

The details matter too: 600-thread-count cotton fabric (1200 threads per inch) with 15 stitches per inch and double-layer down barriers—zero escaping filaments, per FTMS military standards. Every label clearly lists all specs, with third-party test reports from IDFL (the leading U.S. down lab) available online. No vague marketing, just transparency—exactly what the FTC mandates for trustworthy bedding.

From cluster selection to final inspection, apsmile follows "transparency and standardization"—so you pay for quality, not hype. This winter, wrap yourself in an apsmile goose down duvet and let nature’s air-trapping magic keep you cozy all night long. It’s the hotel grand white goose down comforter feel you love, right in your own bed.